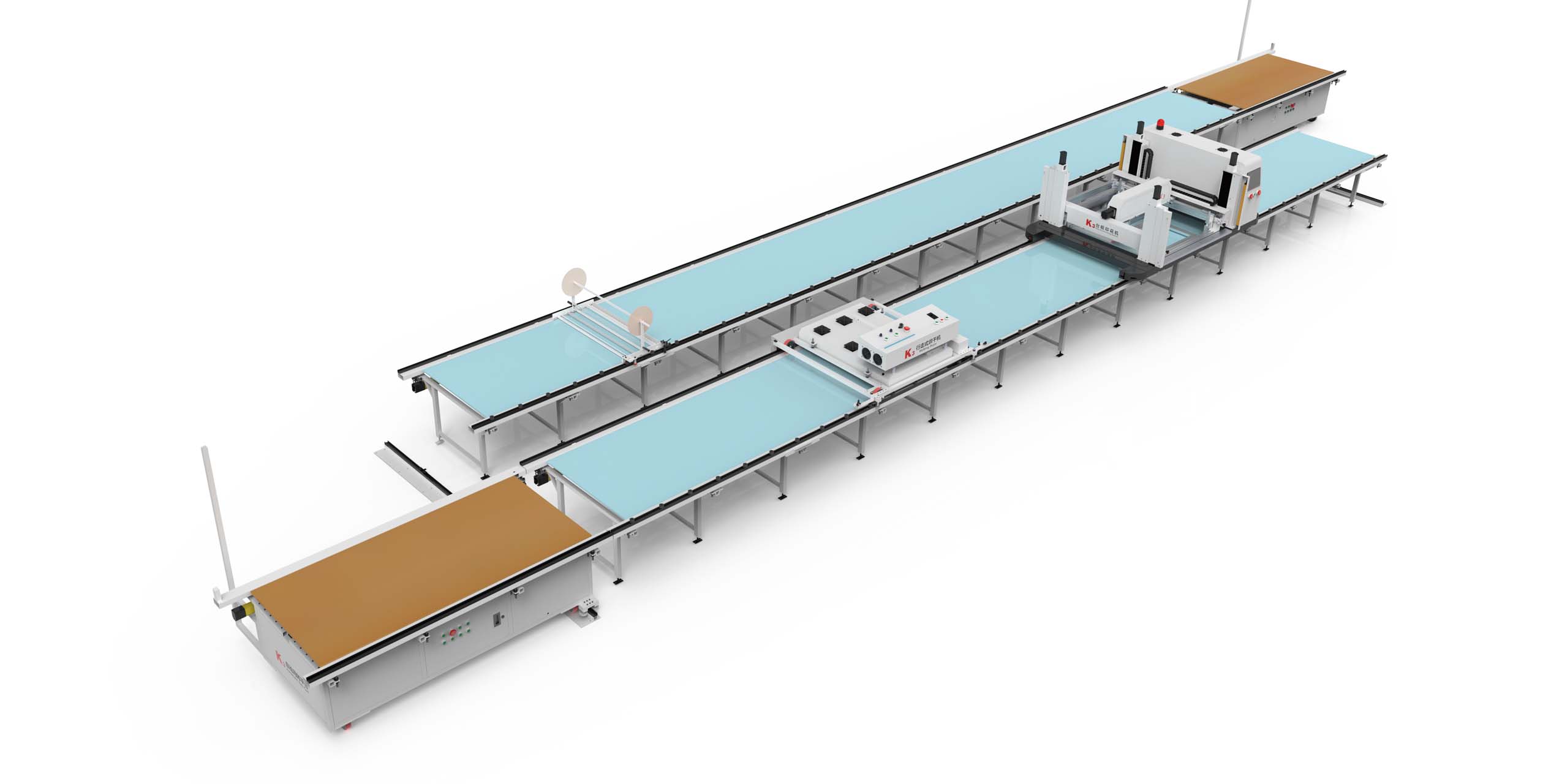

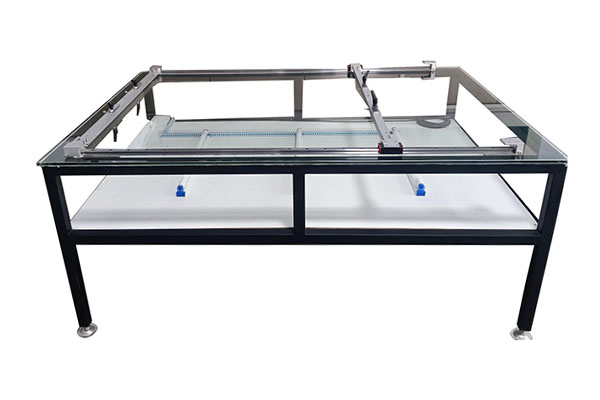

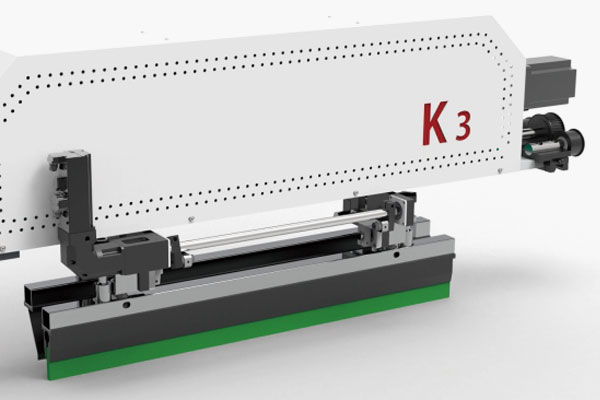

K3 Table Screen Printing Production Line

Product Basic Introduction

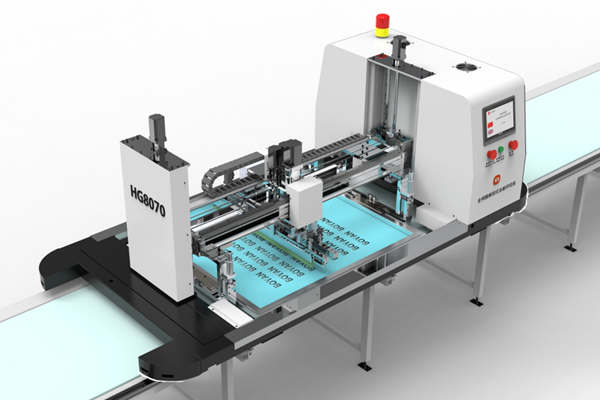

The table screen printing production line is an advanced screen printing production line device that offers two printing modes: vertical (perpendicular to the length direction of the flatbed) and horizontal (parallel to the length direction of the flatbed). This expands the options for screen printing, comprehensively enhancing the flexibility and efficiency of the screen printing industry. It adopts a fully electric drive system, simplifying complex operations in the screen printing process, ensuring that every operator can easily, stably, and efficiently complete high-quality screen printing tasks.

Features

| Flexible Printing Mode | Supports vertical printing (perpendicular to the flatbed length direction) and horizontal printing (parallel to the flatbed length direction), meeting different printing needs. |

| Customizable Printing Area | The printing area can be customized from 600mm×650mm to 3400mm×3800mm, flexibly adapting to the printing needs of different products. |

| High Printing Efficiency | Completes one printing cycle every 3.5 seconds, reaching up to 1028 cycles per hour, significantly improving production efficiency. |

| Large Printing Area | The maximum customizable printing area is 3400mm×3800mm, adapting to printing tasks of different scales with high output. |

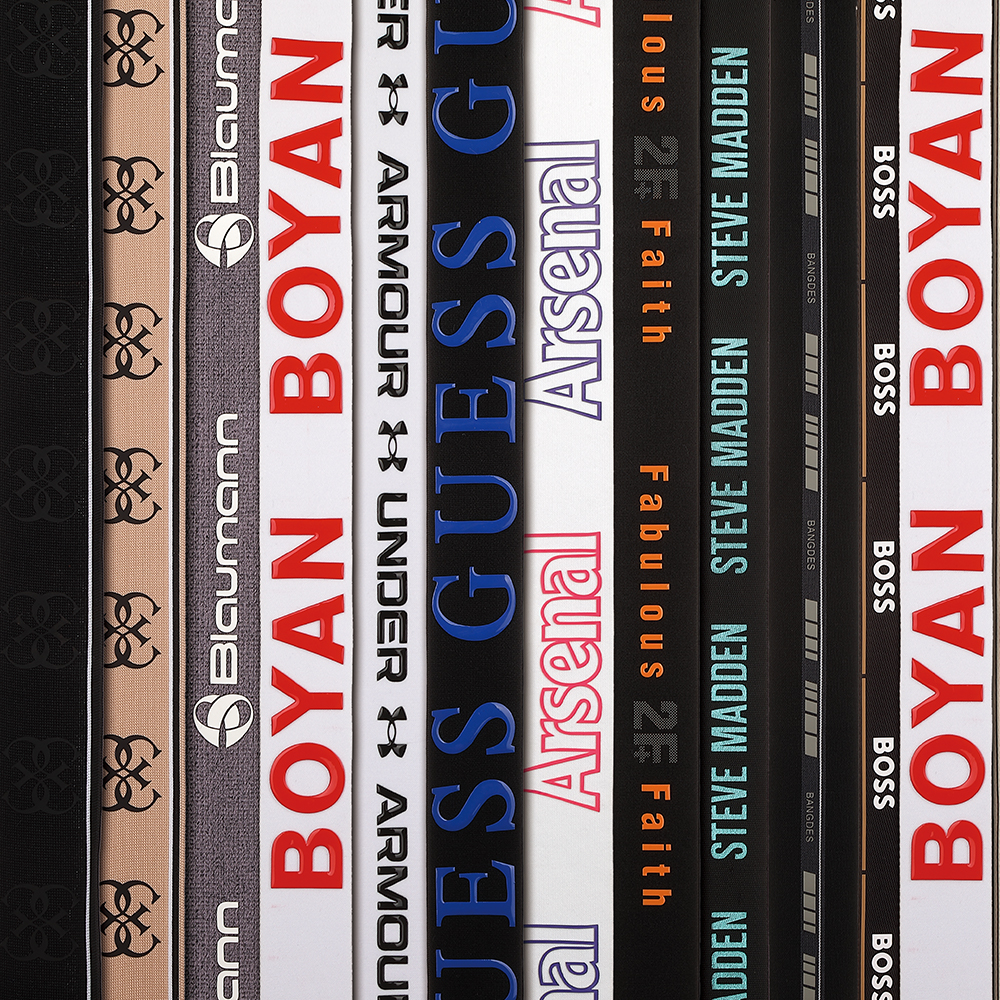

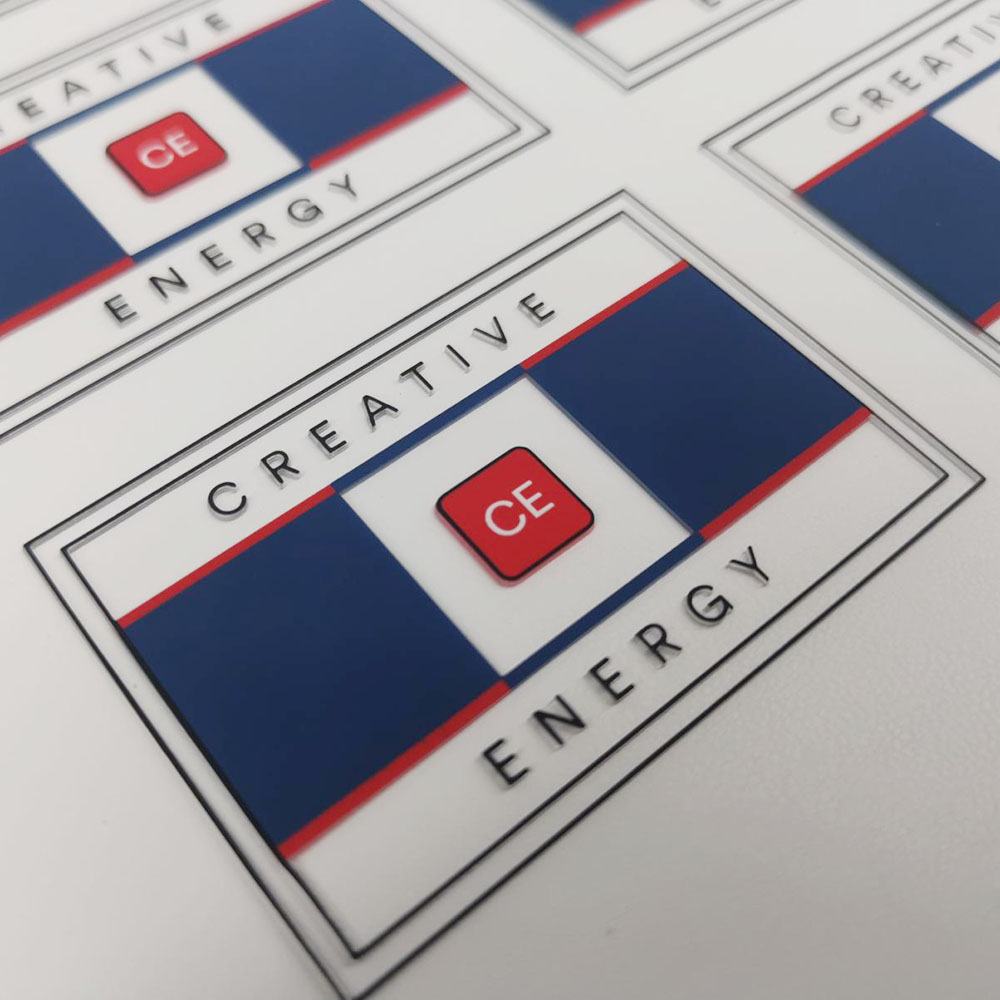

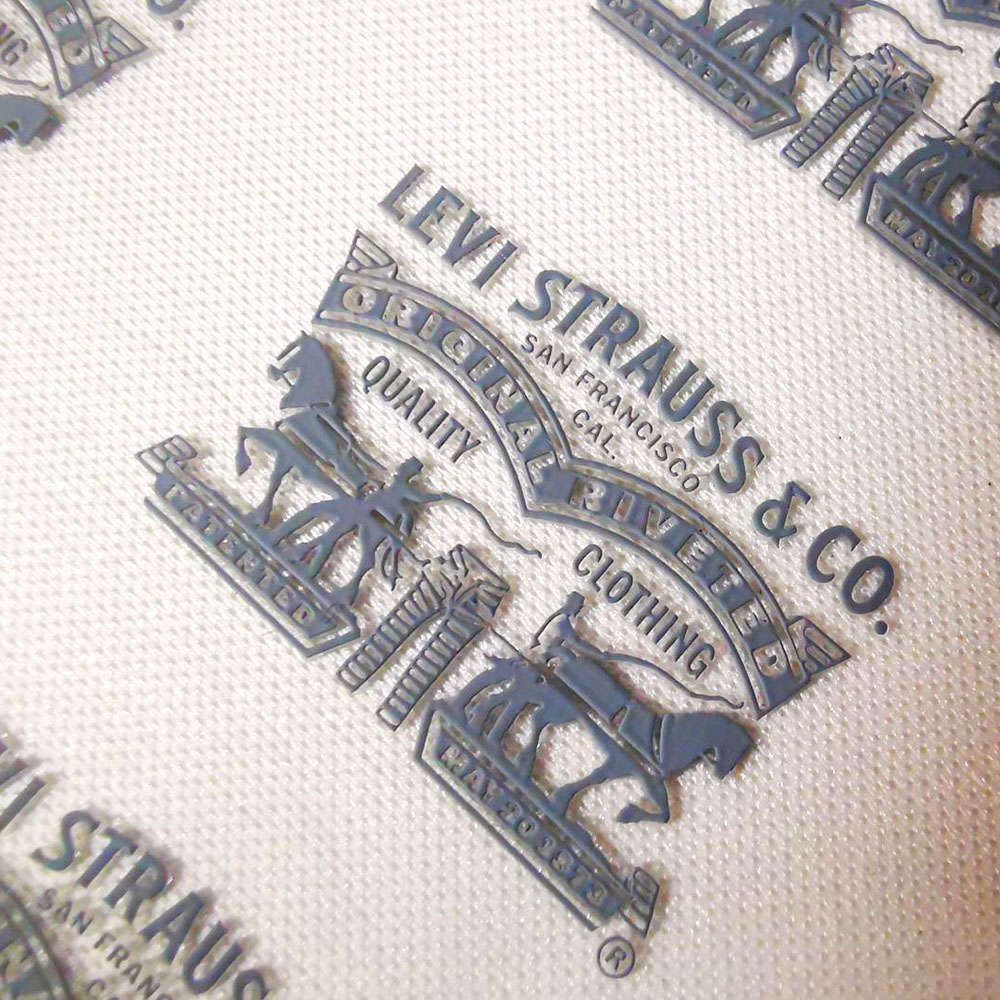

| Wide Material Compatibility | Can print on various flat materials, such as non-woven fabrics, leather, canvas, cotton, flat fabrics (like clothing pieces), shoe materials, 600D bag fabrics, and fabrics (stretch fabrics), webbing (elastic webbing) for direct printing, meeting the needs of different fields. |

| Diverse Printable Product Types | Suitable for printing needs of over 50 categories, such as label printing, heat transfer printing, webbing printing, garment piece printing, shoe material printing, bag printing, umbrella printing, artificial plant printing, hat printing, mobile phone case printing, etc. |

| Multi-Ink Compatibility | Supports various inks, including hot oil inks, silicone, pulp, water-based pastes, glue, water-based inks, gold powder, UV oil, and more, meeting the application requirements of different products. |

| Fully Electric Drive System | Adopts a fully electric drive system, simplifying the printing operation process and making complex movement and printing operations easy and efficient. |

| High-Precision Operation | Equipped with a precise travel and positioning system, ensuring consistent printing cycle speed and stable printing quality. |

| High-Quality Printing Effect | Ensures uniform and clear printing effects through optimized mechanical structure and precise positioning technology, meeting high-quality printing requirements. |

Product Highlights

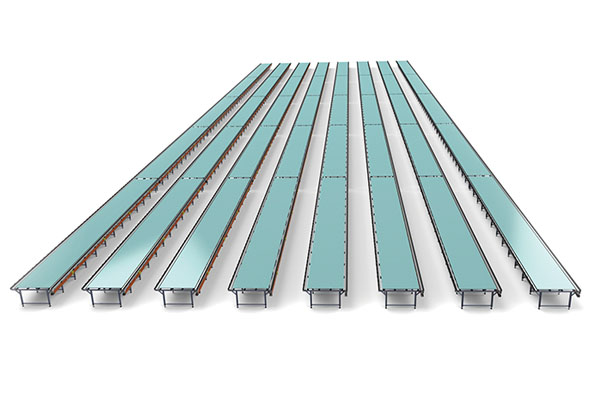

The K3 table screen printing production line is a comprehensive screen printing solution integrating automation, intelligence, and high efficiency. The production line consists of flatbed printing machines, walking dryers, and automatic transfer platforms, which work in coordination to build a “high-efficiency, smooth, and stable” intelligent screen printing system. It not only upgrades the screen printing industry from the “manual screen printing era” to the “automatic screen printing era” but also truly realizes automatic material transfer and equipment scheduling after the flatbed printing machine completes printing. This optimizes the workflow and provides screen printing factories with a stable, reliable, and all-round solution. Below are the main advantages of the K3 flatbed printing production line:

Automation Improves Production Efficiency

The K3 table screen printing production line adopts a fully automated system. The flatbed printing machine replaces the repetitive operations of traditional manual plate making, reducing the threshold for screen printing technology. It can precisely control the pressure and stroke during printing, ensuring the consistency and uniformity of each print. Automated operations not only improve production efficiency but also greatly reduce the possibility of human error, ensuring the stability of printing quality.

Precise Printing Effect

The K3 table screen printing machine uses high-precision mechanical design and advanced drive systems, ensuring that each scraper stroke achieves uniform pressure distribution and consistent printing effects. Through a sophisticated control system, printing pressure and scraper angle can be adjusted precisely as needed, avoiding uneven phenomena that may occur in traditional manual printing. The quality of each print can be maintained consistently, ensuring the high standards of the final product.

Intelligent Automatic Transfer Table

The K3 automatic transfer table can automatically complete the repositioning of tables and seamless connection between devices. After the table screen printing machine finishes printing on the current table, the K3 table screen printing machine can automatically connect to the transfer table, which will accurately transport it to the next production line or table. In this way, the printing machine can continue operations on the next table. This automated transfer function greatly enhances the continuity and efficiency of production.

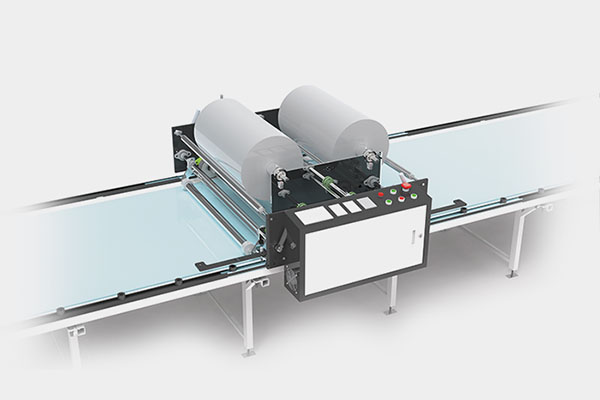

Walking Dryer Ensures Efficient Drying

For the processing of printing materials such as silicone and pulp, the walking dryer plays a crucial role.

It can quickly and evenly dry materials after flatbed printing, avoiding quality issues caused by uneven drying or excessive drying time.

The working speed of the dryer perfectly matches the production rhythm of the flatbed printing machine, ensuring that each batch of products is thoroughly dried and ready for the next step.

Product Application Fields

The K3 table screen printing production line can be widely used in over 50 industries, including textile printing, shoe and bag printing, textile material printing, and webbing printing. It is an ideal screen printing equipment for printing enterprises to transform from traditional manual operations to automation and standardization. Its strong compatibility and scalability enable it to easily adapt to various production needs, achieving an accurate, efficient, and sustainable screen printing solution.

Compatible Material Types

Various fabrics such as cotton, polyester,nylon

Silicone sheet, PVC film, heat transfer film, PU material

Various webbing, elastic bands, flat leather materials

Paper, artificial leather, faux leather, flocking materials, etc.

Compatible Printing Materials

Water-based pastes, pulp, hot oil inks, UV inks.

Silicone, foaming paste, hot melt paste, flocking paste.

Hot stamping paste, glue, special thermal transfer oil inks, etc.

Additional Notes

The K3 table screen printing production line is applicable to:

High-demand three-dimensional silicone rubber printing

High-demand three-dimensional silicone rubber printing

A printing project with rich colors, clear layers and complex craftsmanship

Scenarios where manual printing is difficult to achieve stable batch output

Optional configurations

Scenarios where manual printing is difficult to achieve stable batch output

One-stop shopping, easy upgrade

There is no need to spend a lot of time choosing screen printing consumables and screen printing equipment. K3’s full set of screen printing services provides you with a one-stop procurement solution. Contact us and you will get:

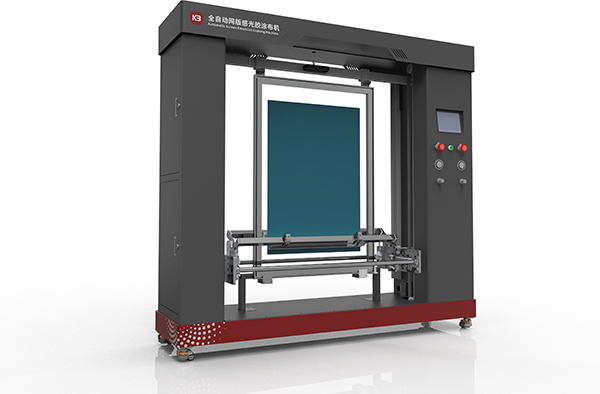

K3 4 pillar Vertical Table Screen Printing Machine (Screen Printer)

K3 Walking Dryer

K3 Walking UV Curing Machin

Fully automatic table plate hot pressing and flattening machine

K3 Screen Printing Precision Machine Table

K3 Fully Automatic Tension Closed-Loop Screen Stretching Machine

K3 Automatic Screen Developing and Washing Machine

K3 Screen Transfer Cart

K3 Drying, Registration, Exposing 3-in-1 Machine

K3 Precision plate alignment platform

K3 Automatic Screen Emulsion Coating Machine

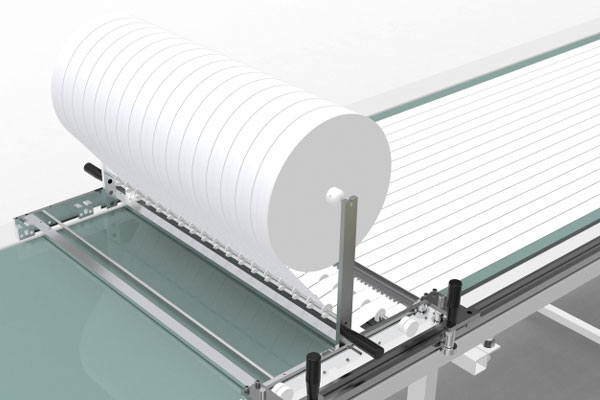

K3 Tape Laying Machine

K3 Fully automatic tension and deviation correction integrated machine

K3 Fully Automatic Fabric laying and winding Machine

Screen printing squeegees, silk screen squeegees, PU squeegees

K3 Silk-screened aluminum mesh frame

Other consumables for screen printing equipment

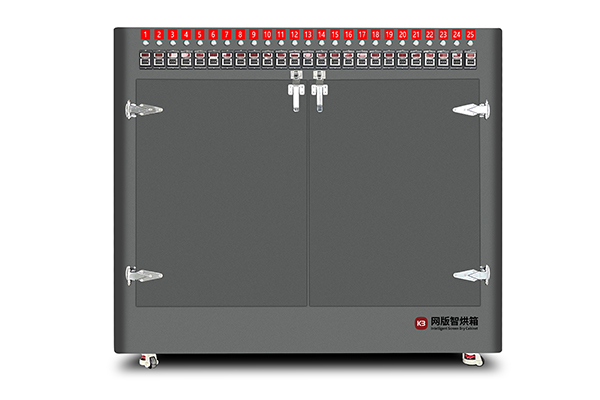

K3 Intelligent Screen Drying Cabinet

The K3 plate printing production line, with high efficiency, high stability and intelligent collaboration as its core, integrates multiple links such as printing, drying, turnover and plate making, completely solving the pain points of unstable printing and limited production capacity in traditional printing. Whether it’s large-scale printing tasks or complex and diverse process requirements, K3 can provide you with reliable support, helping enterprises achieve standardized, large-scale and intelligent upgrades in screen printing.

From automated printing equipment to auxiliary drying, UV curing, and precision plate-making systems, K3 is not just a single machine, but a complete set of future-oriented printing solutions. It can not only significantly enhance the efficiency and quality of printing, but also optimize the human resource structure, reduce long-term operating costs, and create truly sustainable productivity for your factory.

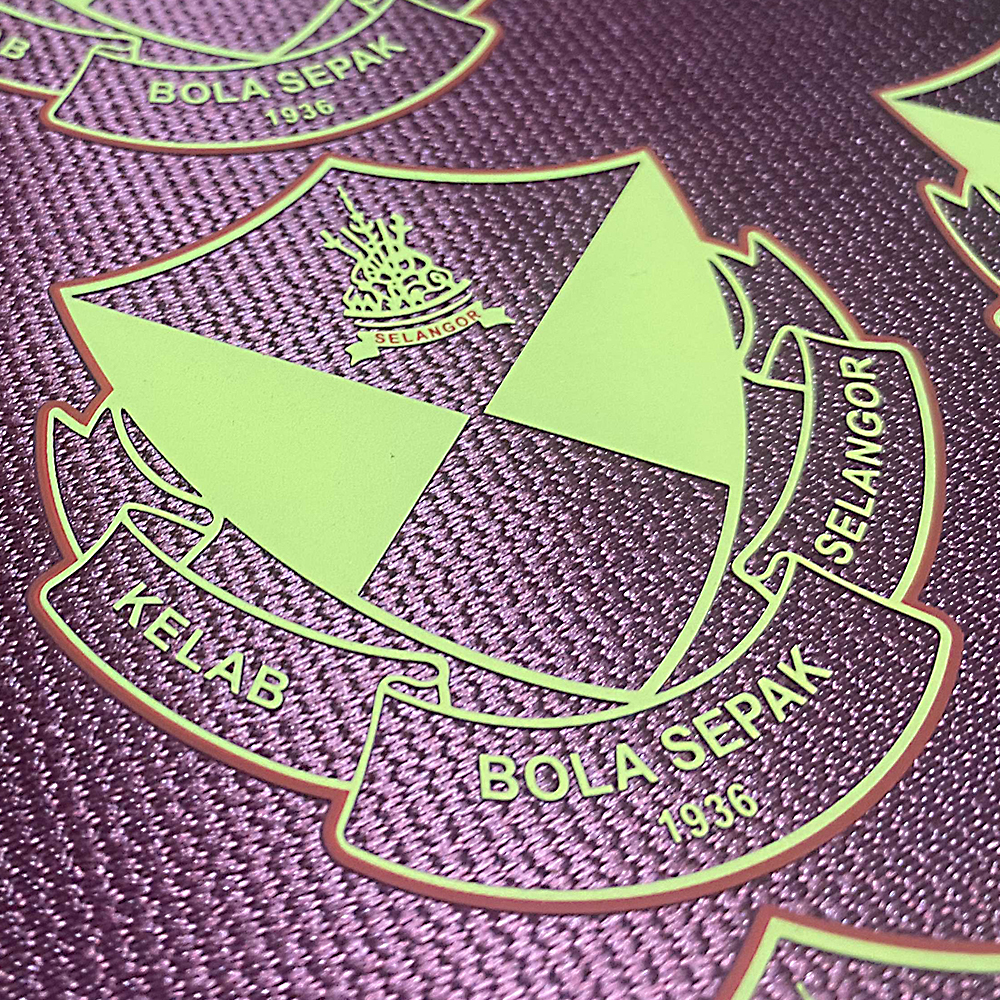

- If you are looking for a set of products with outstanding printing precision that can keep up with the strict printing quality requirements of international big brands

- If you want to reduce your dependence on the technical level of the printing master

- If you are considering expanding production and upgrading or establishing a standardized printing workshop,

Then, the K3 flatbed printing production line is precisely your ideal choice!

Contact us now to get exclusive solutions and quotations, and start your path to efficient and intelligent printing!

Supports customized configuration, provides sample testing, and offers remote guidance for installation and commissioning

It has been widely applied in over 1,600 well-known printing enterprises worldwide, and its quality and reputation are trustworthy!