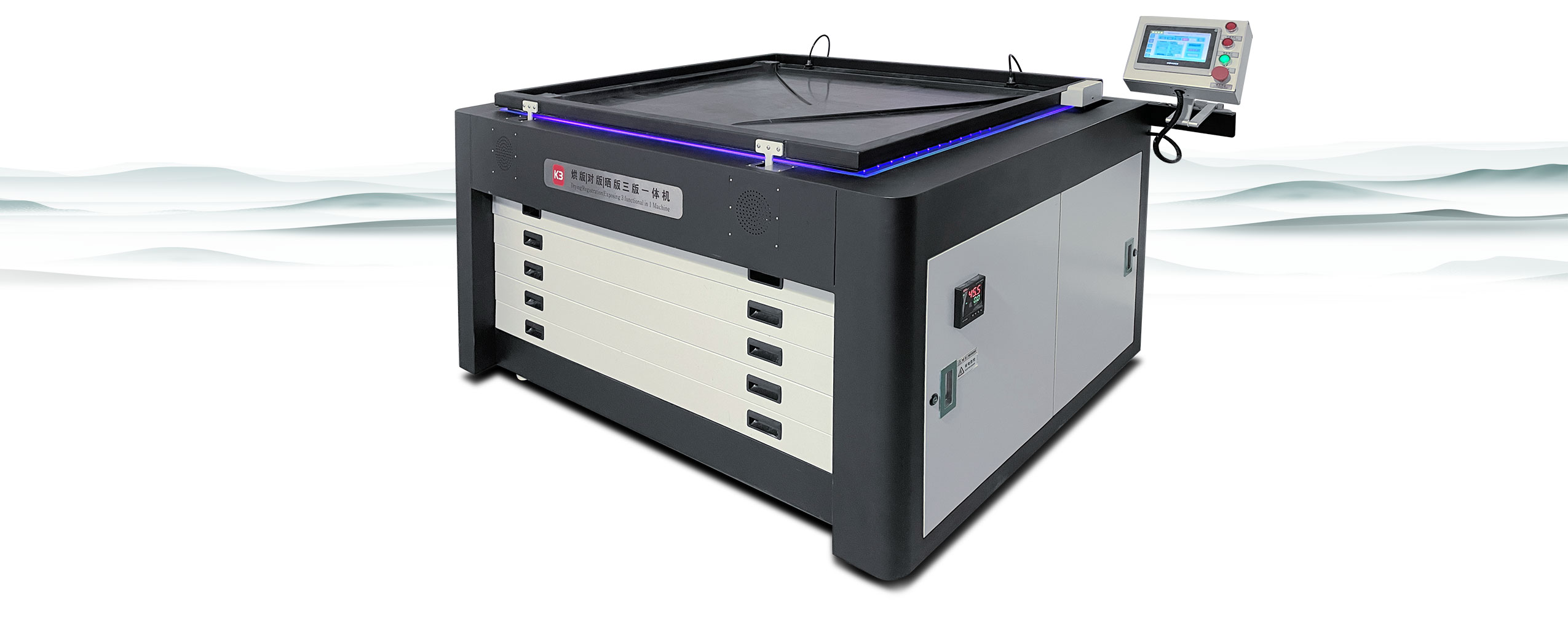

K3 Drying, Registration, Exposing 3-in-1 Machine

The K3 Drying, Registration, Exposing 3-in-1 Machine is a multifunctional pre-press plate-making device for screen printing that integrates drying, registration and exposure functions. By combining the capabilities of a drying machine, registration machine and exposure machine, it solves pain points in traditional plate-making processes such as scattered equipment, space waste and inaccurate alignment, greatly improving plate-making efficiency and precision for large printing factories.

Basic Introduction

The device adopts a 5-layer drawer-type plate storage design, paired with a 6kW hot air circulation system to achieve rapid drying of photosensitive emulsion; it uses film alignment technology to ensure precise registration for each exposure; its vacuum-free vertical pressing system prevents screen stretching and deformation, ensuring 1:1 pattern fidelity during output. Equipped with a high-density UV-LED exposure system and 6063-T5 aluminum substrate, it delivers high-energy, uniform exposure results. It is suitable for high-efficiency pre-press plate-making needs in multiple fields such as garment printing, electronic printing, labels and crafts, making it an ideal choice for energy-saving screen printing plate-making.

Applications

The K3 all-in-one machine is widely used in the pre-press plate-making stage of screen printing. It integrates three core functions: drying photosensitive emulsion, precise multi-color registration and LED exposure. It is suitable for high-quality plate-making requirements in industries such as garment printing, label printing, shoe material printing, webbing printing, identification production, electronic components and circuit boards, significantly improving plate-making efficiency and precision.

Features

| Three Core Functions in One | Integrates drying of photosensitive emulsion, precise multi-color registration and LED exposure in a single device, saving space. |

| Reduce Equipment Costs | Combines three devices into one, saving workshop space and lowering overall investment costs. |

| 5-Layer Drawer-Type Design | Adopts a 5-layer drawer-type plate storage design to hold more screens, facilitating screen replacement and storage. |

| High-Temperature Constant Hot Air | External 6kW hot air circulation heating system provides adjustable constant temperature up to 50℃, enabling rapid drying of photosensitive emulsion. |

| Precise Film Alignment | Equipped with a film alignment system to ensure accurate registration; alignment is completed before exposure. |

| Vacuum-Free Adsorption | Uses vacuum-free screen adsorption via mechanical elastic flat pressing, ensuring tight bonding of the film, screen and plate, and solving pattern deformation issues to achieve 1:1 high-fidelity pattern output. |

| High-Fidelity Output | High-density UV-LED exposure system with powerful performance, sufficient energy and fast exposure speed. |

| Highly efficient UV-LED exposure | High-density UV-LED exposure system, with high power and sufficient energy, provides efficient exposure and excellent exposure effect. |

| High-Quality Aluminum Substrate Design | Adopts 6063-T5 aluminum substrate with good flatness and fast heat dissipation, ensuring uniform energy distribution and more balanced exposure results. |

Advantages

Integrated Plate-Making Solution

Precise Registration Output

High-Fidelity Pattern Output

Faster Drying Time

Higher Exposure Efficiency

Simpler Operation

Enhanced Safety

Long Service Life

Technical Parameters

| Equipment Model | DGNUVLED90120 |

| Main Machine Dimensions | L1740mm W1350mm H990 |

| External Cabinet Dimensions | L700MM W370mm H850 |

| Maximum Screen Area | 900mmX1200mm |

| Total Power | 9Kw |

| Power of the plate drying box | 6Kw |

| Drying Chamber Temperature Range | Room Temperature — 50℃ |

| Light Source | UVLED |

| UVLED Power | 2Kw |

| Control Mode | PLC Full Automatic |

| Display Interface | Touch Screen |

| Registration Method | Film Alignment |

| Screen Fixing Method | Mechanical Vertical Gravity Bonding |