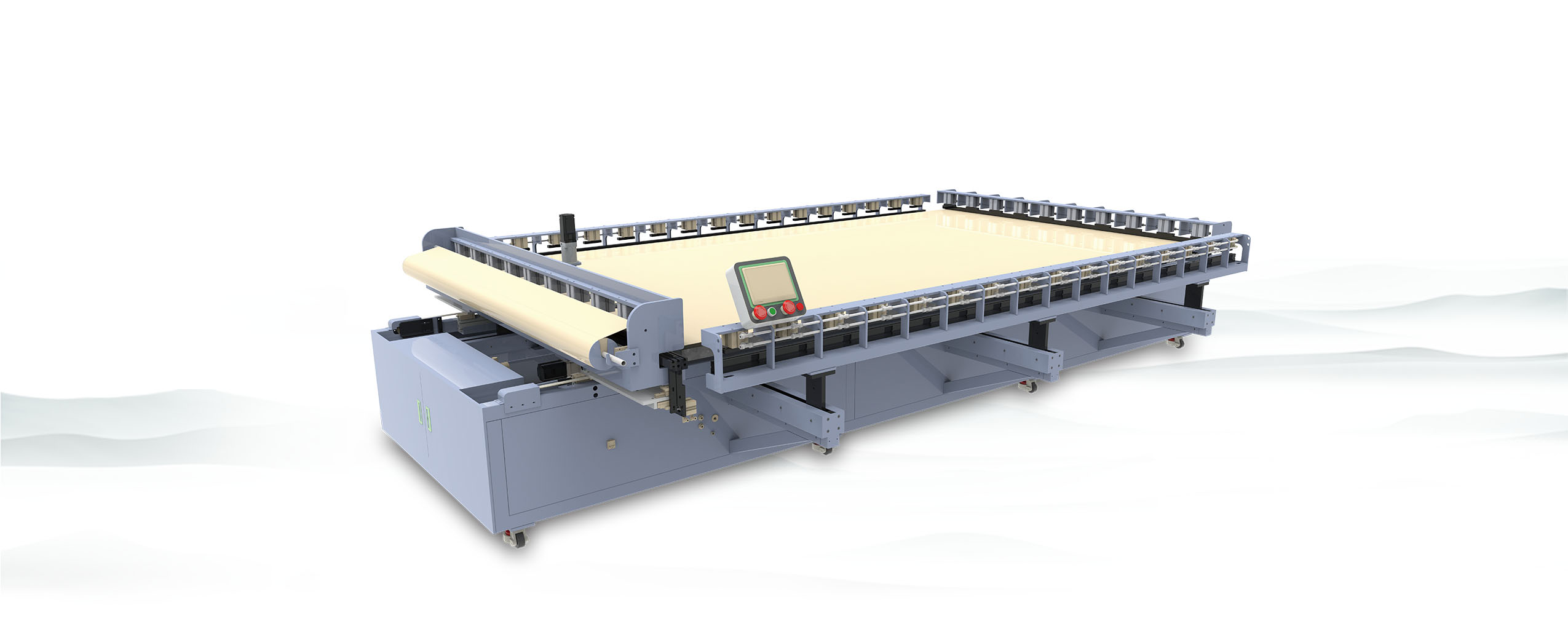

K3 Fully Automatic Tension Closed-Loop Screen Stretching Machine

The K3 Automatic Tension Closed-Loop Screen Stretching Machine (Model: AIA 1550) is a high-end screen stretching device integrating closed-loop tension control, automatic screen stretching, automatic mesh locking, and high-speed mesh stretching. It adopts full servo drive and digital closed-loop tension control technology, and innovatively equips the QuadraSync four-axis synchronous tension balancing system. It is widely used in printing, electronics, textile, and new energy industries, ensuring stable tension output and efficient production.

Features

Tension Closed-Loop Control

Equipped with a digital tension meter + full closed-loop control system, it monitors and dynamically adjusts tension in real time with an accuracy of ±0.5N, preventing deformation or breakage caused by uneven screen tension.

K3经典产品

High Precision & Efficiency

Full servo drive system supports fast mesh locking in <10 minutes, with micron-level position control accuracy, meeting the needs of high-speed continuous production.

K3经典产品

Intelligent Flexible Adjustment

Screen frame thickness ranges from 20-50mm, and angle supports multi-gear adjustment (22.5°/45°/90°) with one-key switching, adapting to diversified process requirements.

K3经典产品

Automated Production

The intelligent control system enables fully automatic mesh locking, reducing manual intervention, lowering operation error rates, and improving consistency.

K3经典产品

Servo Top-Lifting Mechanism

Servo-driven four-corner mesh top-lifting mechanism, smooth and precise, meeting high-quality screen production standards.

K3经典产品

QuadraSync Four-Axis Synchronous Tension Balancing System

clamping mechanism and servo drive technology, realizing precise tension distribution during screen stretching. Through closed-loop feedback mechanism, each side has 0.5N dynamic tension compensation, keeping the tension deviation of the four sides ≤1.5%. This effectively avoids common problems in traditional manual operations such as uneven tension and edge stress concentration. This technology greatly improves screen flatness, meeting ISO 9001:2015 Class 3 standards, reducing single-job time by 40%, and increasing finished product yield from 78% (manual operation) to 98.6%. It is especially suitable for applications requiring consistent substrate tension, such as high-precision silk screens and optical films.

K3经典产品

Technical Parameters

| Project | Parameter description |

| Maximum Working Size | 1500mm × 3000mm |

| Screen Frame Thickness Range | 20mm – 50mm |

| Single Mesh Locking Time | < 10 minutes |

| Screen Angle Adjustment | 22.5° / 45° / 90° |

| Tension Control Accuracy | ±0.5N |

| Mesh Locking Mode | Fully Automatic |

| Tension Control Mode | Digital Tension Meter + Closed-Loop Control System |

| Intelligent Control System Functions | |

| Touch Screen Operation | User-friendly human-machine interface, displaying real-time tension data, equipment status and alarm information. |

| Tension Curve Monitoring | Each group of tension change curves is visible, facilitating analysis and debugging. |

| Multi-Group Parameter Storage | Supports quick switching between different production plans, improving production efficiency. |

| Fault Self-Diagnosis System | Automatically identifies abnormal tension or machine failures, providing visualized alarms and solutions. |

| QuadraSync Four-Axis Synchronous Tension Balancing System | Ensures consistent mesh tension through intelligent tension management and dynamic compensation technology, significantly improving screen flatness and production efficiency. Suitable for applications such as high-precision silk screen printing. |

Functions of the intelligent control system

| Touch screen operation | The humanized human-machine interaction interface displays tension data, equipment status and alarm information in real time |

| Tension curve monitoring | Each group of tension changes is clearly visible, facilitating analysis and debugging |

| Storage of multiple sets of process parameters | Supports quick call of different production plans to improve production efficiency |

| Self-diagnosis system for faults | Automatically identify abnormal tension or mechanical faults, and provide visual alarms and solution suggestions |

| Four-dimensional synchronous tension balancing system | Through intelligent tension management and dynamic compensation technology, the consistency of the screen tension is ensured, significantly improving the flatness of the screen surface and production efficiency. It is suitable for applications such as high-precision screen printing |