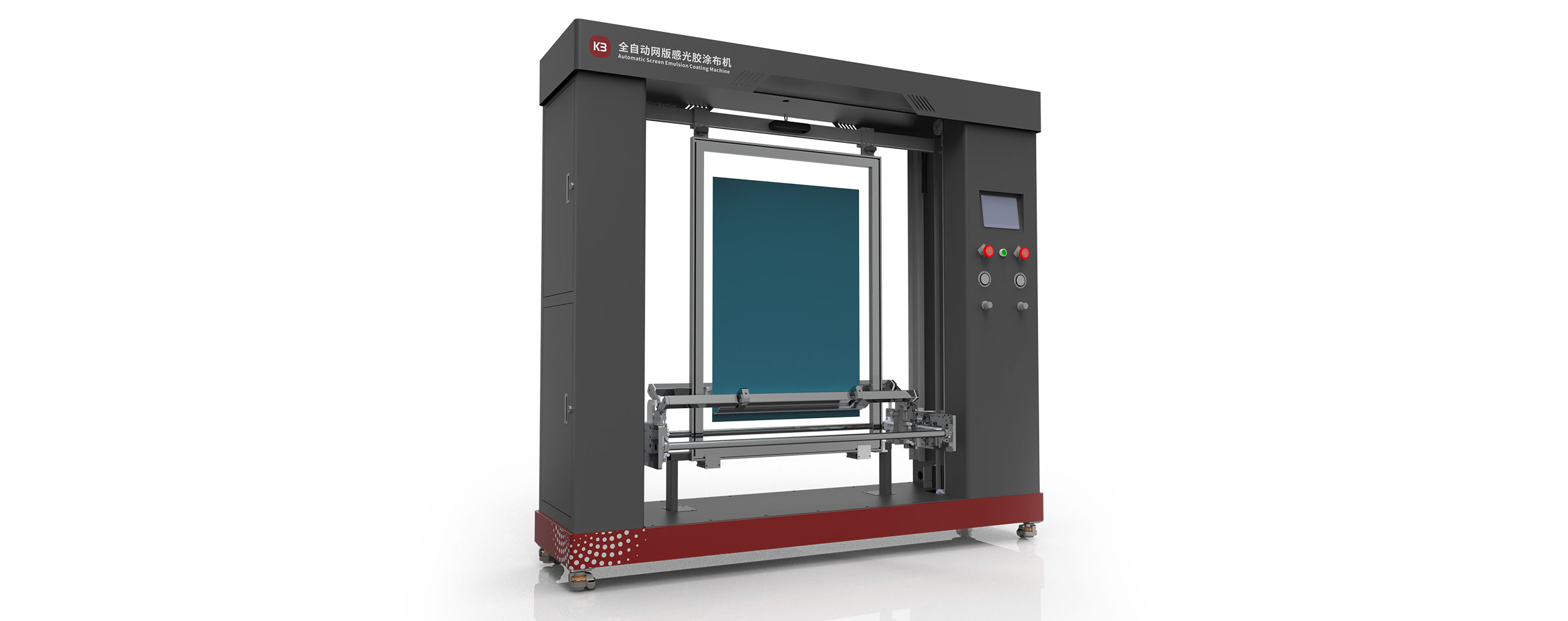

K3 Automatic Screen Emulsion Coating Machine

K3 Automatic Screen Emulsion Coating Machine is an efficient and precise device designed for the screen printing industry, mainly used for photosensitive emulsion coating of silk screens. It is suitable for high-quality screen printing, especially for coating photosensitive emulsions on large screens and extra-large-format screens. Manual coating is often laborious and unstable for such screens. K3 Automatic Screen Emulsion Coating Machine precisely controls the coating thickness and uniformity of the screen through its coating system, which greatly reduces material waste, improves the accuracy and stability of screen coating, and ensures uniform coating on each screen surface, thereby enhancing the quality of the final printed products.

Product Basic Introduction

K3 Automatic Screen Emulsion Coating Machine is particularly suitable for applications with high requirements for screen quality and coating layers, such as high-end garment printing, label printing, webbing printing, shoe material printing, ribbon printing, fabric printing, and high-precision industrial printing.This machine can stably produce high-quality screens, meeting the needs of fine patterns, complex designs, and large-format printing. It ensures high-standard, high-precision printing results, perfectly meeting customer requirements.

K3 Automatic Screen Emulsion Coating Machine is equipped with advanced dual-servo four-cylinder uniform coating technology, which can precisely control the thickness of each coating layer, avoiding uneven coating and unstable coating problems that often occur in traditional coating methods. At the same time, the pneumatic pressure plate design can effectively solve the problem of uneven screen frames, ensuring that every screen can achieve a uniform coating layer, greatly improving production efficiency and yield.

K3 Automatic Screen Emulsion Coating Machine adopts an open automatic internal frame system, which facilitates quick replacement of screen printing plates and replenishment of photosensitive emulsions, reducing downtime and improving production flexibility. The machine’s high-efficiency coating speed and precise coating accuracy can adapt to different production volumes, minimize material waste, and improve production efficiency. It helps screen printing factories ensure consistent product quality while increasing production volume.

K3 Automatic Screen Emulsion Coating Machine provides a precise and efficient solution for screen printing factories, making it an ideal device for improving printing quality and production efficiency.

Features

| Pneumatic Pressure Plate | Integrated design of pneumatic pressure plate and rigid pressure plate ensures flat screen frames, solving the problem of uneven photosensitive emulsion coating caused by uneven screen frames. |

| Dual-Servo Four-Cylinder Uniform Coating | Dual-servo four-cylinder technology precisely controls coating thickness; coating efficiency is higher than traditional methods, and intelligent operation improves production efficiency. |

| Open Automatic Internal Frame System | Open internal frame system facilitates quick replacement of screen plates and replenishment of photosensitive emulsions. |

| Coating Thickness Control | Coating thickness accuracy can reach ±0.002mm, ensuring uniform coating and precision. |

| High-Efficiency Coating Speed | Adjustable coating speed, with a coating efficiency range of 10mm/200mm per second, meeting different production needs. |

| Wide Screen Compatibility | Supports various screen sizes, with applicable screen frame ranges from 500mm×500mm to 1500mm×3600mm, adapting to multiple production requirements. |

| Flexible Frame Thickness | The applicable frame thickness ranges from 20mm to 60mm, enabling the equipment to meet the needs of different customers. |

| Automated Operation | Equipped with automatic operation, it provides a convenient user experience and efficient production capacity, reducing manual intervention and improving production efficiency. |

Product Features

Precise Coating

Intelligent Control

Uniform Coating

Easy Operation

Product Application Fields

The K3 table screen printing production line can be widely used in over 50 industries, including textile printing, shoe and bag printing, textile material printing, and webbing printing. It is an ideal screen printing equipment for printing enterprises to transform from traditional manual operations to automation and standardization. Its strong compatibility and scalability enable it to easily adapt to various production needs, achieving an accurate, efficient, and sustainable screen printing solution.