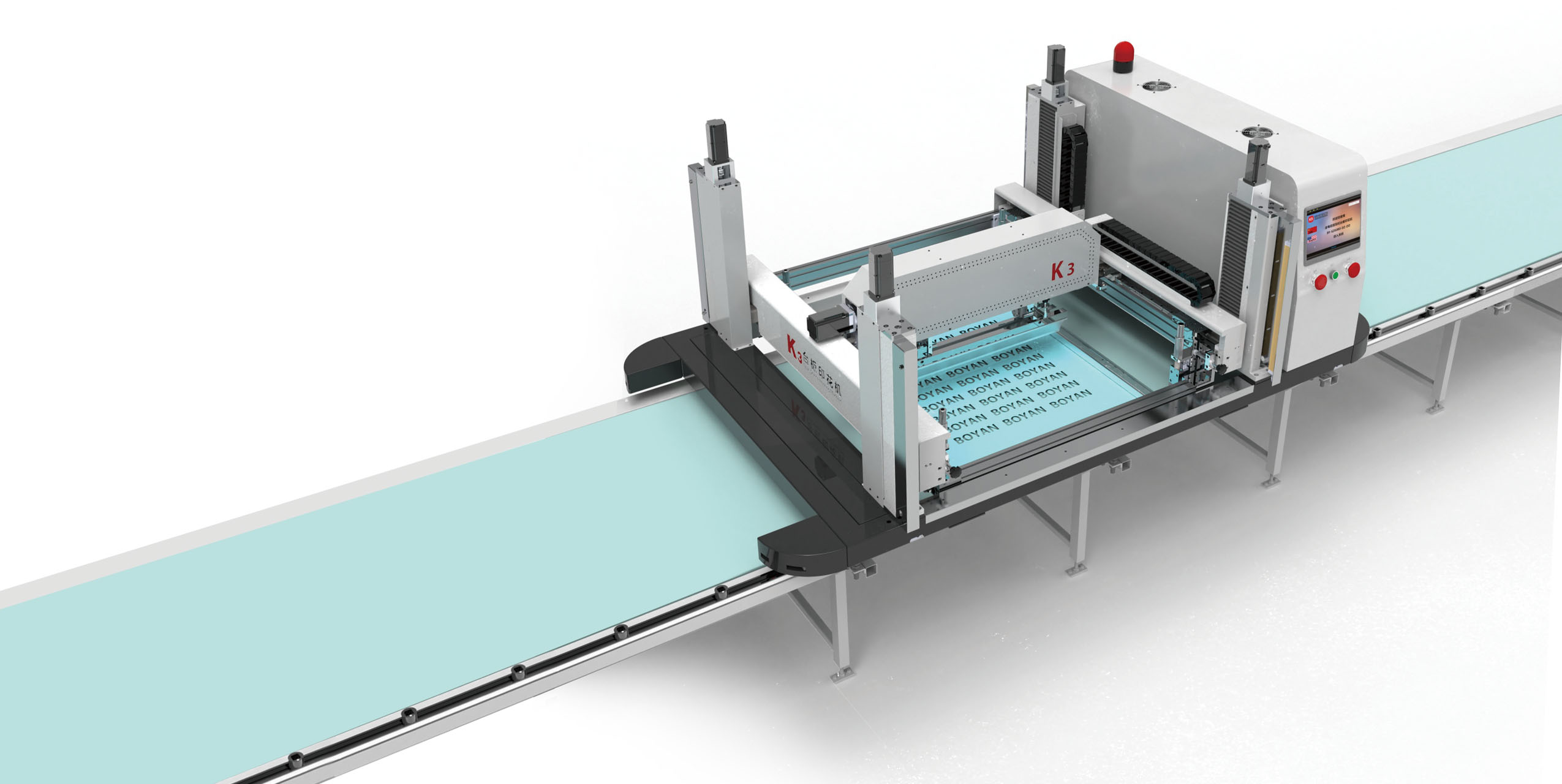

K3 4 pillar Vertical Table Screen Printing Machine (Screen Printer)

The K3 4 pillar Vertical Table Screen printing machine is designed for high-precision, multi-color three-dimensional screen printing. It supports multi-color overprinting and is applicable to various printing materials, including garment pieces, fabrics, webbing, PVC, and mesh fabrics. It is widely used in industries such as clothing, shoe materials, mobile phone cases, hats, boxes, and labels.

Product Basic Introduction

With its high precision, efficiency, and versatility, the K3 4 pillar Vertical Table Screen printing machine meets the needs of large-area, multi-color, and thick-film three-dimensional printing. Whether for complex multi-color overprinting or printing that requires extremely high repeat precision, the K3 can provide an excellent solution.

Features & Parameters

| High-Rigidity Machine Base | Integral welded design, high rigidity, low deformation, and high precision. |

| Triple Positioning System | Servo, Hall, and mechanical triple positioning ensure stable operation of the entire machine. |

| Four-Column Synchronous Lifting | Lifting stroke up to 400mm, making screen replacement easy and ensuring production efficiency. |

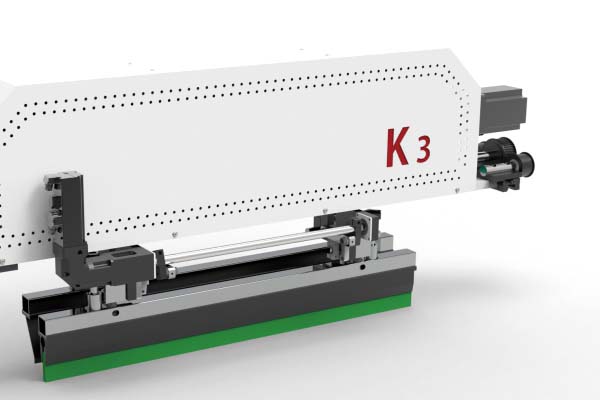

| Linear Guide + Servo Scraper | The scraper moves smoothly with less vibration, improving printing quality. |

| Pre-Registration Device | Shortens machine setup time and improves utilization rate. |

| Adjustable Scraper Angle & Pressure Elasticity | Meets various special process requirements. |

| Photoelectric Anti-Collision System | Four-corner photoelectric positioning ensures operational safety; automatically alarms and stops when encountering obstacles. |

| High-End Servo System | Servo drive system ensures stable production line operation. |

Product Advantages

| Printing Area | Customizable, ranging from 600mm×650mm to 3400mm×4800mm. |

| Multi-Color Overprint Capability | Supports 4×8 color overprinting, compatible with color and composite processes. |

| High Repeat Precision | Repeat printing precision of the same screen frame is ≤±0.02mm; color registration precision is ≤±0.04mm. |

| Wide Applicable Ink Range | Suitable for silicone, pulp, hot oil ink, gold powder, and other materials. |

| Rich Process Range | Supports foaming, flocking, pulling, embossing, four-color dot, and other composite processes. |

| Strong Adaptability | Compatible with over 50 product categories such as clothing, shoe materials, bags, textiles, and labels. |

| High Production Efficiency | Printing speed reaches 360–1200 prints/hour; supports 7×24 hours of continuous operation. |

Application Fields

The K3 flatbed printing machine helps customers improve production efficiency and ensure printing quality, especially demonstrating great advantages in mass production and high-precision scenarios.

Garment Printing

Shoe Materials & Bags

Label Printing

Webbing Printing

Fabric Printing

Couplets Printing

Special Processes

Hat Printing

Optional accessories

Optional accessories

We offer a variety of specifications of screen frames to adapt to different sizes and types of screens

Screen printing squeegees

Scrapers of different materials and types can be selected as needed

silk screen squeegees

It is suitable for various inks and printing materials, ensuring stability even after long-term use

Application Cases

The K3 4 pillar Vertical Table Screen Printing Machine has been successfully applied in multiple fields, widely used in mass production and scenarios requiring sophisticated processes. Typical cases include:

High-End Clothing Label Printing

fashion apparel (such as sportswear, t-shirts, underwear). Customers use the K3 printer to achieve high-quality silicone labels with bright colors, strong three-dimensionality, and no color fading issues.

Shoe Material & Bag Printing

soles, and bags to meet customization needs. Through multiple printings, complex multi-layer patterns are completed, ensuring uniform colors and clear details.

Large-Batch Fabric Printing

In large-batch fabric printing, theK3 4 pillar Vertical Table Screen Printing Machine effectively improves production efficiency and ensures the precision and consistency of product printing, especially suitable for the production of high-end fabrics and customized patterns.

Trademark and label printing

When the customer was manufacturing high-quality woven label fabric trademarks and other labels, they utilized the K3 printing machine to complete complex multi-color overprinting and thick-film three-dimensional printing. The final product quality met the standards and conformed to the quality standards of international brands

Printing of couplets and decorative items

The K3 four-column table plate printing machine has also played a significant role in the traditional festival supplies market, especially in the printing of couplets and Spring Festival couplets, quickly and accurately completing large-scale production

Application of innovative processes

Successfully handling various special processes such as foaming, flocking, and thermosetting inks, it can maintain efficient production and ensure product quality when printing highly precise trademarks, decorative patterns, and three-dimensional designs