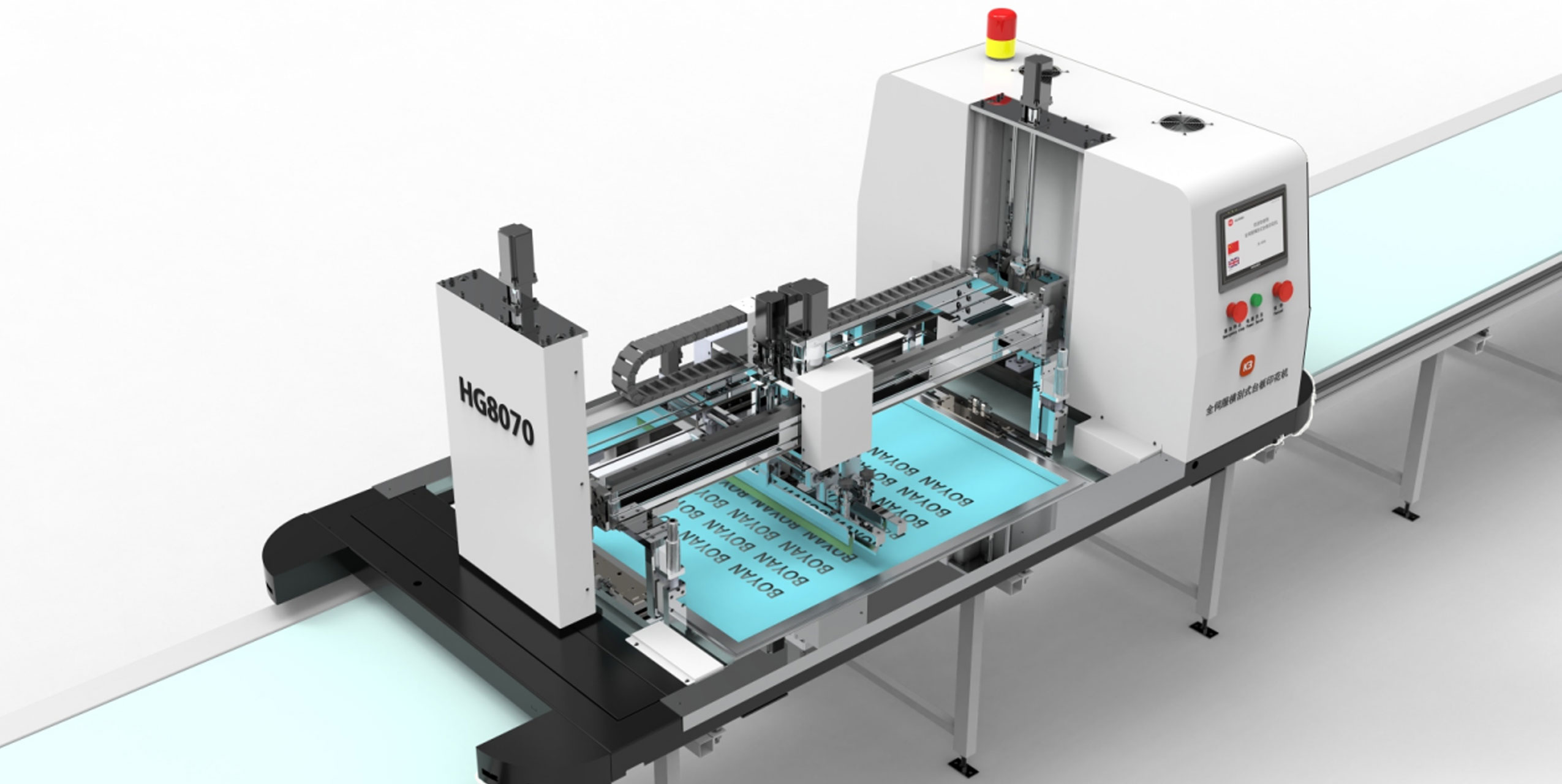

K3 horizontal table screen printing machine

(screen printing machine)

Product introduction

K3 horizontal table screen printing machine is an industrial-grade screen printing machine driven by a full servo system. It is an industrial equipment designed for high-precision, high-efficiency screen printing. Adopting gantry movement technology, it breaks through the limitations of traditional printing machines, especially excels in large-format materials (1.5m×1600mm) and continuous multi-colorization; its modular design supports variable printing areas (from 800mm×600mm to 3500mm×1600mm), and has obvious advantages in multi-color printing precision and production efficiency, which can meet the strict production needs of industries such as clothing, shoes, bags, webbing, and labels.

K3 horizontal table screen printing machine is designed for high-precision, large-batch screen printing. It is suitable for the complex pattern printing of flexible materials such as clothing, shoes, bags, and webbing. It supports special processes such as multi-color printing and 3D embossed printing, which helps improve production efficiency and product quality.

Why Choose

the K3 Gantry-Type Flatbed Printing Machine?

Full Servo Motion System: Adopts dual servo motors + closed-loop control to ensure stable knife movement, with a printing precision of ±0.02mm and uniform color registration.

Intelligent Knife Adjustment: The knife pressure and angle can be adjusted digitally without manual re-calibration, greatly reducing the difficulty of operation. Superior Printing Consistency: Higher color registration precision and more stable pattern replication.

Ultra-high Stability: Integrated four-in-one gantry frame, strong deform ability resistance, and can maintain ultra-fine precision during long-term high-speed operation; the equipment has a service life of up to 10 years.

Wide Applicability: Can print various materials such as ink, silicone, paint, and UV, and supports special processes such as 3D embossed printing and stud printing.

Features & Parameters

| High-rigidity machine base | Integral welding design, high rigidity, minimal deformation, and high precision |

| Triple positioning system | Three positioning methods (servo, Hall, and mechanical) ensure stable operation of the whole machine |

| Four-column synchronous parallel lifting | Lifting stroke up to 400mm, convenient for wiping and cleaning, ensuring production efficiency |

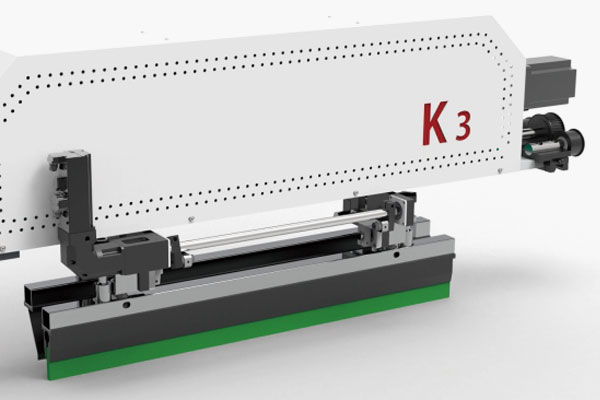

| Linear guide + servo knife | Stable knife running, reduced vibration, and improved printing quality |

| Pre-registration device | aves plate printing time and improves efficiency |

| Adjustable knife angle and pressure elasticity | Meets various special process requirements |

| Photoelectric anti-collision system | Four-corner photoelectric induction ensures operation safety; automatic alarm and stop when people are detected |

| High-end servo system | Servo drive system ensures stable production operation |

product quality

Full Closed-loop Servo System: Dual-view servo + triple sensor positioning, with a micro-movement precision of ±0.02mm.

Full Control of Knife Adjustment: Digital control of pressure and angle, reducing manual intervention and improving consistency.

Wide Compatibility: Adapted to 48 kinds of color inks, covering multiple fields such as clothing, home textiles, and industrial labels.

Check which model suits you! If there is no suitable model for you? Contact me to customize a special machine!

Model | Maximum printing area | Glass width | Maximum frame size | Mechanical repeatability accuracy | Printing efficiency (times/hour) |

BY-HG8060-DZ-DD | 800×600 | 780 | 1200×900 | ±0.02 | 900 |

BY-HG1610-DZ-DD | 1600×1000 | 1300 | 2000×1400 | ±0.03 | 800 |

BY-HG2016-DZ-DD | 2000×1600 | 1900 | 2400×2000 | ±0.04 | 650 |

Choosing the right model not only boosts your production efficiency but also ensures optimal printing quality. If you find the above models don’t fully meet your needs, don’t worry! We offer custom-made specialized models, which can be tailored to your specific requirements.

Contact us to customize a specialized model—we’ll provide a tailored solution to help you improve production efficiency and printing quality while reducing production costs.

Application Fields

The K3 horizontal table screen printing machine can help customers enhance production efficiency and ensure printing quality. It demonstrates great advantages especially in large-batch production and high-precision scenarios.

Textile industry

Package & printing

Industrial products

Special materials

Standard accessories

The K3 horizontal table screen printing machine can help customers improve production efficiency and ensure printing quality. It shows great advantages especially in large-batch production and high-precision scenarios.

Screen Frame

The integrated design of the pneumatic push-rod rigid backplane effectively presses the screen frame, keeping the four corners of the micro-register screen frame in a flat state. This solves the problem of uneven ink transfer caused by an uneven screen frame.

Scraper

The digital system for doctor blade pressure and angle makes relying on experience a thing of the past. Printing quality becomes repeatable and controllable, enabling digital and standardized operations.

Wear-Resistant Strip

It maintains shape stability during high-pressure and high-frequency operations, avoiding a drop in printing accuracy caused by deformation.

Customization Options

The K3 horizontal table screen printing machine is not just a piece of equipment, but a high-efficiency printing solution that enhances a company’s competitiveness. Whether for small-batch customization or large-batch production, it can deliver faster speed, lower defect rates, and higher profit returns to boost your business.

K3 Walking Dryer

Used to dry semi-dry printing materials (such as silicone, paste, ink) during the printing process.

K3 UV Curing Machine

Mainly used for rapid curing and drying of coating or ink layers. It uses an ultraviolet (UV) light source to trigger a chemical reaction, quickly converting the coating or ink from a liquid state to a solid state.

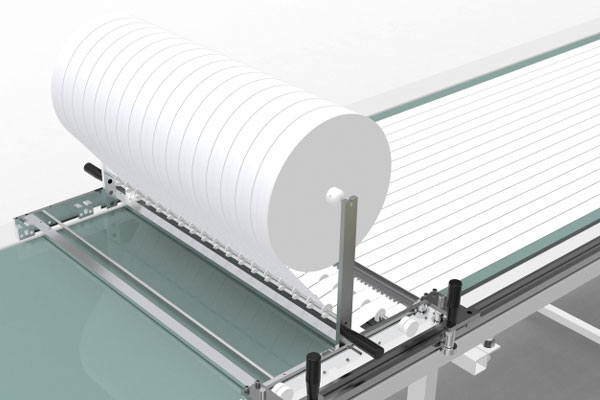

Roll Material Equipment

With elastic positioning: the positioning wheel is always in contact with the aluminum profile linear guide rail. The belt conveyor adopts a secondary guiding and positioning design, ensuring accurate belt placement and high efficiency.

Application Scenarios

The K3 horizontal table screen printing machine has been successfully applied in multiple fields, and is widely used in large-batch production and scenarios with delicate process requirements. Below are some practical application cases:

High-end Clothing Label Printing

Multi-color printing and 3D effects are widely used in label and pattern printing for fashion apparel such as sportswear, T-shirts, and sweaters. By using the K3 printing machine, customers have achieved high-quality continuous labels with bright colors, strong 3D effects, and no color fading issues.

Fabric and Ribbon Printing

In large-batch fabric printing, the K3 four-column tabletop printing machine effectively improves production efficiency while ensuring the precision and consistency of product printing. It is especially suitable for the production of high-end fabrics and customized patterns.

Shoe and Luggage Printing

The K3 table screen printing machine is used for large-area pattern printing on shoe uppers, soles, and luggage, meeting customized needs. Through multiple printing processes, complex multi-layer patterns are completed, ensuring uniform color and clear details.

Logo and Label Printing

When producing high-quality woven fabric logos and other labels, customers used the K3 printing machine to complete complex multi-color printing and thick-film 3D printing. The final products meet quality standards and comply with the brand criteria of international brands.

Couplet and Festival Product Printing

The K3 horizontal table screen printing machine also plays an important role in the traditional festival product market, especially in the printing of couplets and Spring Festival couplets, completing large-batch production quickly and accurately.

Innovative Process Applications

Successfully handles various special processes such as foaming,flocking, and hot-melt ink. When printing high-precision labels, decorative patterns and three-dimensional patterns, it can maintain efficient production while ensuring product quality.