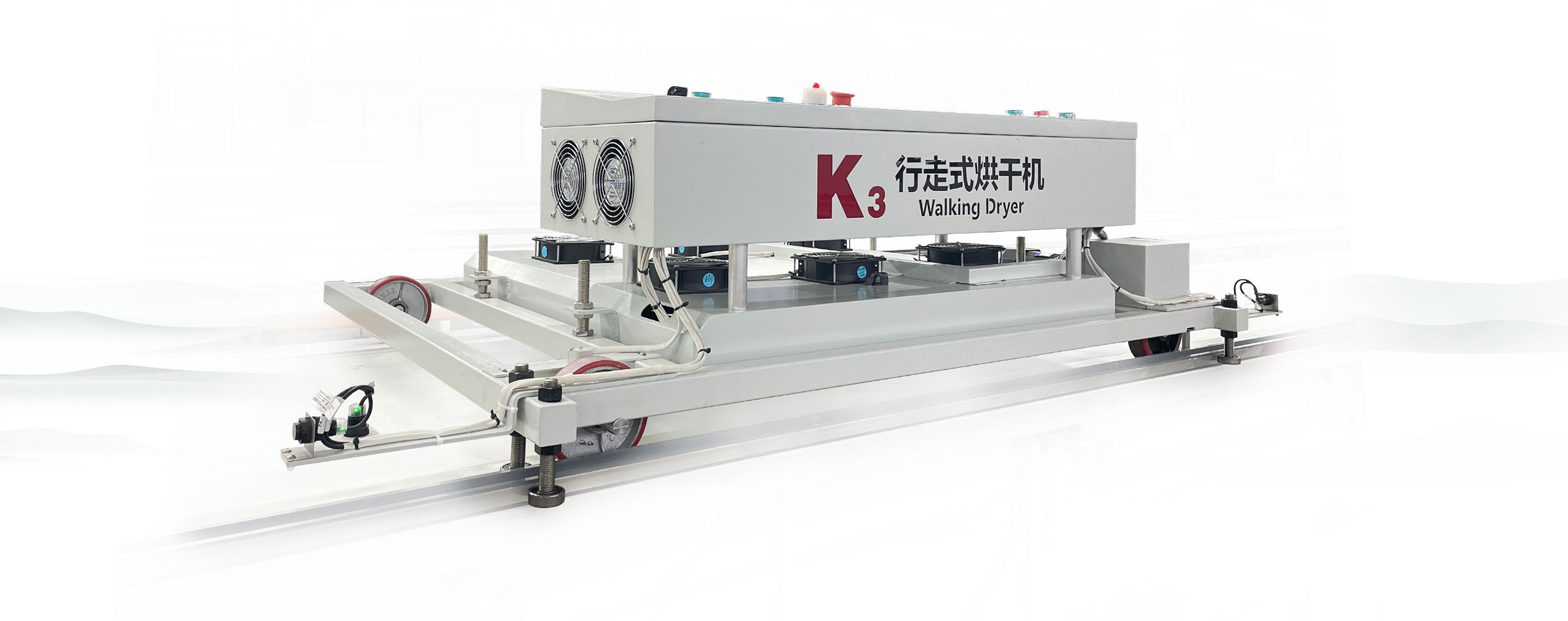

K3 Walking Dryer

The K3 walking dryer is a high-efficiency drying device specially designed for the flatbed screen printing industry. It is widely used for drying treatments of glue, pulp, and ink. It adopts an 800mm carbon fiber tube, which provides strong heat energy; the tube can reach a high temperature of 600°C, ensuring uniform and fast drying of various materials. The dryer is equipped with 5-gear constant temperature control, allowing temperature adjustment according to different printing materials to optimize the drying effect.

Product Basic Introduction

The walking speed of the K3 walking dryer can be infinitely adjusted; users can set it freely based on production needs to control heating time. The matrix-arranged fans ensure uniform airflow of hot air, keeping the drying effect of printed products consistent. The machine also supports remote operation: it can be controlled to start/stop, adjust walking direction, and turn the tube on/off within 100 meters, greatly improving operational convenience.

The K3 walking dryer adopts a dual-drive system, avoiding the problem of unstable machine walking and ensuring long-term stable operation. Equipped with a matching anti-damage design: if the dryer reverses or stops abnormally, the tube will automatically power off to prevent damage to printed materials. The overall design performs excellently in efficiency, energy saving, and safety, making it an ideal drying equipment for flatbed printing.

The K3 walking dryer is specially designed for drying semi-dry printing materials. It is widely used in drying treatments during flatbed screen printing processes, and is suitable for drying various materials such as glue, pulp, and ink.

All-Weather Applicability

The walking dryer is equipped with 5-gear constant temperature technology, which can control the temperature precisely within ±1°C in environments ranging from -30°C to 50°C. It efficiently handles extreme cold and humidity, adapting to the four seasons of north and south regions, and ensuring stable curing of glue.

Features

| Strong Heat Energy | 800mm carbon fiber tube with 1.0–1.2kW power; maximum temperature up to 600°C, ensuring uniform drying effect. |

| Controllable Temperature | 5-gear constant temperature control, adjustable according to the needs of different printing materials. |

| Energy-Saving Design | Tube position control: the tube is turned on only when aligned with the printing surface, saving energy. |

| Infinitely Adjustable Speed | Walking speed is infinitely adjustable, convenient for controlling heating time to meet different production needs. |

| Uniform Airflow | Matrix-arranged fans provide uniform airflow, ensuring continuous and stable hot air circulation for consistent drying effects. |

| Remote Operation | Remote control within 100 meters for starting/stopping, left/right walking, and tube on/off. |

| Dual Drive | Single-power dual-drive design avoids gear wear, ensuring stable and safe walking. |

| Automatic Return | Automatically returns when the dryer encounters obstacles during walking, reducing manual intervention and improving production efficiency. |

| Anti-Damage Design | If the dryer reverses or stops abnormally for more than 6 seconds, the tube will automatically turn off to prevent damage to printed materials. |

Advantages

Multifunctional

Flexible Control

Speed Controllable

Energy-Saving and Efficient

Safe and Reliable

High-Efficiency Hot Air Circulation

Technical Parameters

| Product Model | BY-IR6085 | BY-IR6065 | BY-IR8016 | BY-IR8018 | BY-IR1020 | BY-IR1022 |

| Suitable Flatbed Width | 1220mm | 1080mm | 1900mm | 2100mm | 2300mm | 2500mm |

| Outer Rail Track Size | 1480mm | 1300mm | 2260mm | 2460mm | 2660mm | 2860mm |

| Maximum Drying Area | 800mm*1150mm | 800mm*1000mm | 800mm*1850mm | 800mm*2050mm | 800mm*2250mm | 800mm*2450mm |

| Maximum Surface Temperature of Heating Tube | 600±30℃ | |||||

| Heating Tube Power | 1200W | 1000W | 1300W | 1300W | 1400W | 1500W |

| Number of Heating Tubes | 22 | 22 | 22 | 22 | 22 | 22 |

| Heating Tube Length | 660mm | 530mm | 1010mm | 1110mm | 1210mm | 1310mm |