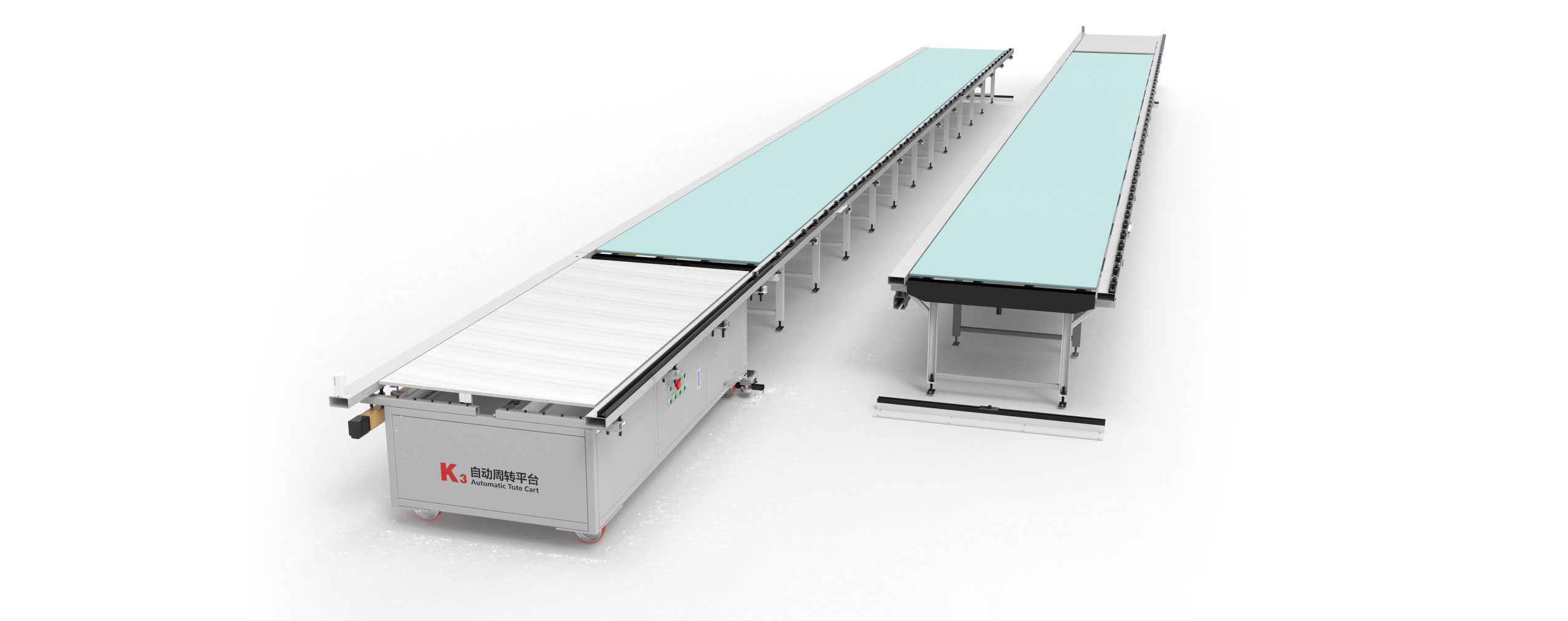

K3 Automatic Turntable

The K3 automatic Turntable is a high-efficiency automated device used for automatically moving and transferring printing equipment between multiple screen printing stations, such as flatbed printing machines, walking dryers, pressing machines, and inserting machines. Through an automated transfer system, it solves the problems of time waste and low production efficiency caused by traditional manual handling and empty board transfer. The platform is equipped with remote control operation, sliding contact power supply, and automatic reset technology to ensure efficient and safe operation.

Product Basic Introduction

The K3 automatic Turntable adopts a low-profile ground rail design, minimizing the impact of uneven floors and making the device run more stably. At the same time, the built-in sliding contact power supply technology avoids traditional cable transmission issues, improving the device’s reliability and safety. It can control the platform’s left/right movement and stop functions via remote control within a 100m range; the operation is simple and intuitive, greatly enhancing the flexibility and work efficiency of the production line.

Whether in high-efficiency screen printing production lines or large-scale equipment transfer workshops, the K3 automatic Turntable provides enterprises with stable and reliable automated equipment transfer solutions. Through automated equipment transfer, the platform optimizes workflows, reduces labor costs, improves production efficiency, and helps enterprises achieve intelligent and automated production upgrades.

Product Features

| Low-Profile Ground Rail Design | Resolves uneven floor issues and maximizes convenience for staff to pass between devices. |

| Multi-Station Mutual Transfer Operation | Supports transfer between multiple devices; remote operation is convenient and fast (controllable within 100m), greatly improving work efficiency. |

| Sliding Contact Connection Technology | The Turntable connects with the station’s sliding contact line, solving power interruption problems during platform transfer and ensuring stable operation. |

| Built-in Sliding Contact Power Supply | The ground rail and the platform’s built-in three-level sliding contact line supply power, while providing power for the printing machine; it is safe and reliable, ensuring stable operation. |

| Automatic Reset Program Design | The automatic reset function ensures reliable and stable operation of the device. |

| Single-Power Double-Drive | Adopts a 400W variable frequency motor, which drives the power wheels through a worm gear to avoid gear wear, ensuring stable and safe operation. |

| Turntable Interaction | The Turntable and equipment exchange information via infrared switches, ensuring safety during transfer. |

| Remote Control Operation Function | Equipped with a remote control function; the platform can be controlled to move left/right or stop within 100m, with convenient operation to improve work efficiency. |

| Overall Equipment Positioning Accuracy | After the Turntable connects with the machine rail, the positioning pin inserts into the positioning hole, ensuring accurate positioning during transfer and avoiding production issues caused by equipment misalignment. |

Advantages

High-Efficiency Transfer

Intelligent Control

Easy Operation

Stable Operation

Application

The K3 automatic Turntable is used for equipment transfer in flatbed printing production lines, such as flatbed printing machines, dryers, pressing machines, etc. Through automated equipment transfer, it improves production efficiency, reduces manual intervention and time waste, and achieves continuous and stable production.