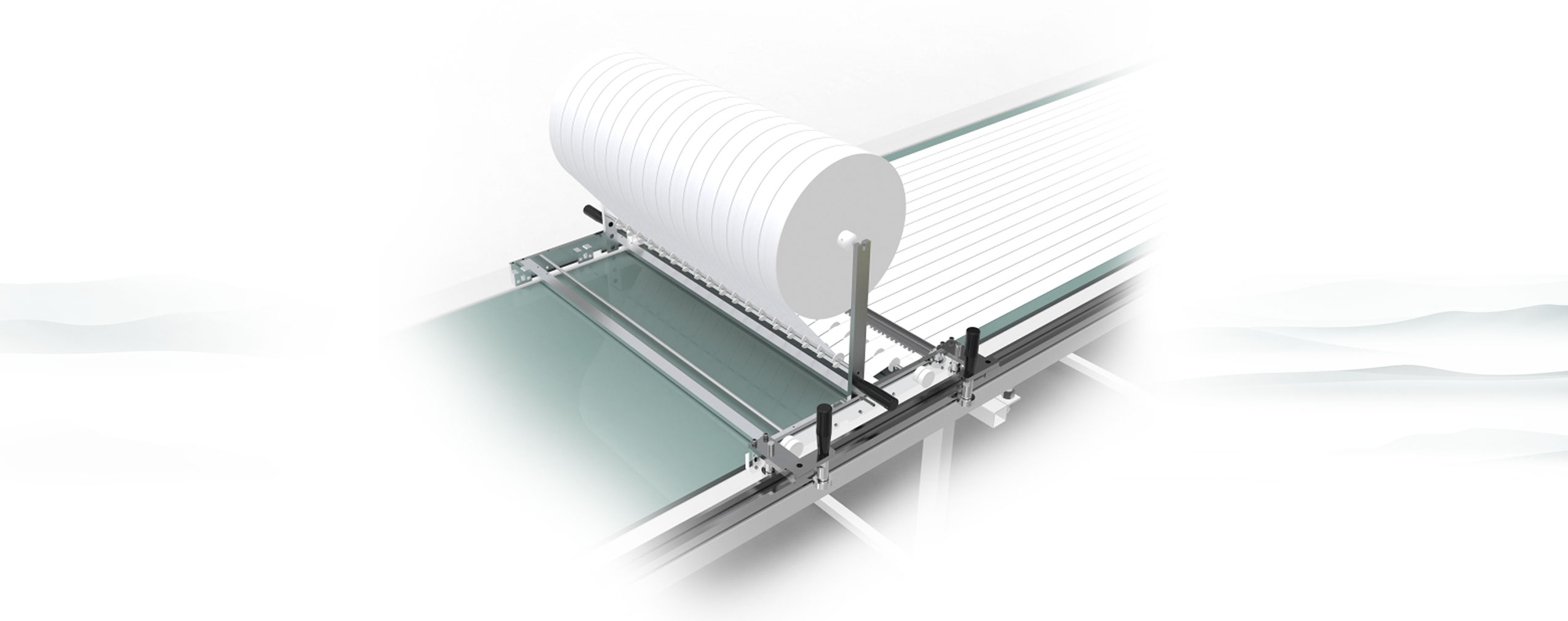

K3 Tape Laying Machine

The K3 Tape Laying machine is designed for flatbed printing processes. It is used to efficiently unwind various webbings (such as elastic webbing, elastic ribbon, etc.) according to specified specifications. It is suitable for continuous strip materials like webbing. When used with flatbed printing equipment, it can accurately and efficiently set up various webbings based on preset parameters.

Through standardized webbing feeding processes, it effectively reduces human errors, avoids printing deviations, comprehensively improves the positioning accuracy of printing patterns and the efficiency of webbing feeding, laying a solid foundation for the printing of webbing products.

Product Features

| Lightweight and Easy to Use | The entire machine is made of aviation materials, which are sturdy and lightweight, saving operational effort. |

| Width Compatibility | Supports 6mm–50mm webbing, meeting diverse process requirements. |

| Modular Design | Plug-in mold structure enables quick replacement, flexibly adapting to different specifications. |

| High-Precision Control | The elastic positioning system ensures the positioning wheel always fits the linear guide rail, improving webbing feeding accuracy. |

| Precise and Efficient | Secondary guiding structure further optimizes the webbing position, enhancing work efficiency. |

Application Fields

It is widely used in fields such as clothing fabrics, luggage manufacturing, and sportswear production. It adapts to the printing needs of webbings of various specifications and materials, improving production efficiency and product consistency.