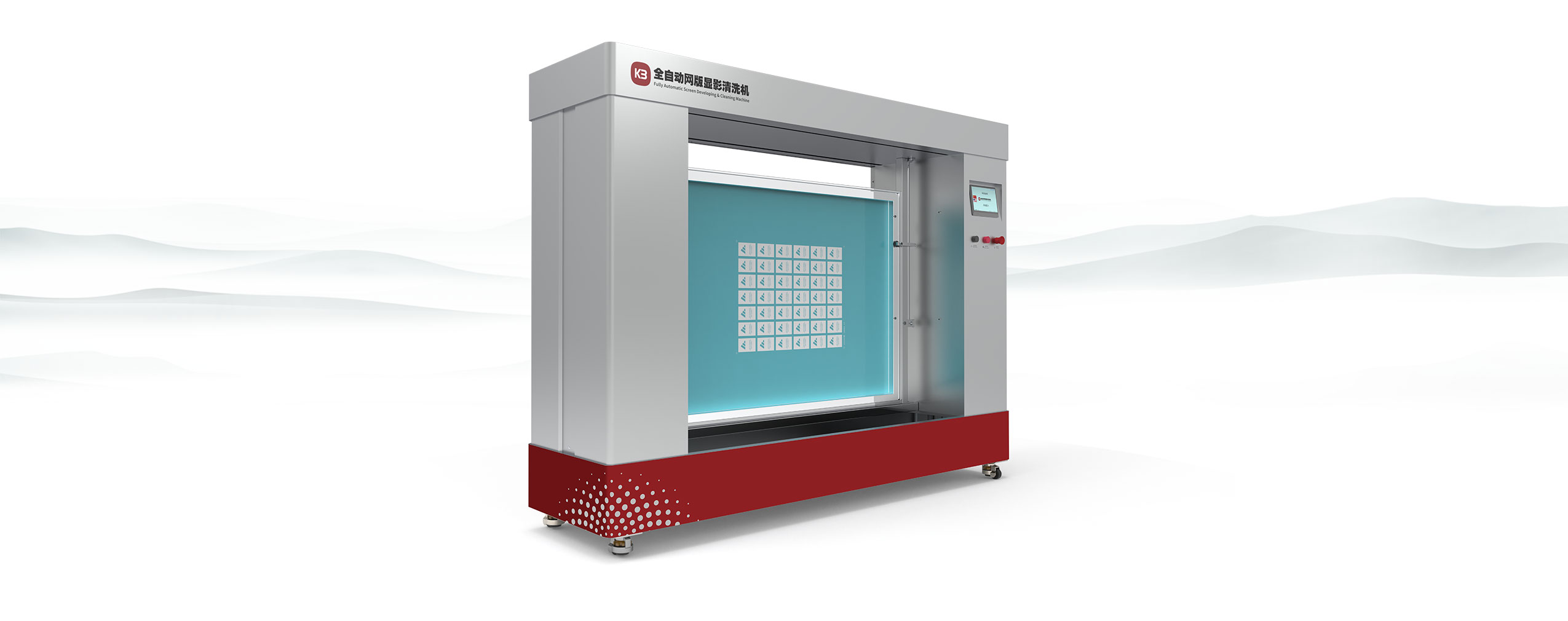

K3 Automatic Screen Developing and Washing Machine

Designed for high-precision screen printing processes, the K3 integrates advanced High-Pressure Gas Spraying (HPS) and Spraying Immersion System (SIS) to achieve damage-free treatment and efficient, energy-saving operation throughout the developing process. It supports left-right water flow alignment, enabling seamless connection with pre- and post-process equipment (such as exposure machines and drying machines). It is an indispensable automated device in industries including textiles, optoelectronics, PCB, and ceramic electronics.

Key Features

High-Pressure Gas Spraying Technology

Atomization particle size ≤50μm, ensuring more uniform developing

Adjustable spray pressure (0-0.3MPa) to avoid damaging the film layer

Water saving rate ≥40%, realizing green environmental protection

Spray-Immersion Dynamic Soaking Integrated System

Developing speed increased by 30%

Effectively wets complex pattern areas for thorough developing

Intelligent Automated Control System

20 groups of process parameter storage, adapting to different materials and application scenarios

Reserved RS485/MODBUS interface for easy connection to production line automation

Technical Parameters

| Parameter | Specification |

| Maximum screen size | 1200 × 1500 mm (customizable) |

| Developing speed | 60-120 pcs/min (depending on pattern complexity) |

| Air pressure | 0.6-0.8 MPa (adjustable) |

| Water flow | ≤50 m³/min (HPS mode) |

| Water consumption | ≤8L/㎡ (HPS mode) |

| Power supply/power | AC380V 50Hz / 5.5kW |

| Control system | 7-inch touch screen + PLC |

Model Specifications

| Model | Development Technology | Screen size | Cleaning Type | version |

| BOYAN-ADH-120-Mk2 | HPS High-pressure Spray | 120×150cm | Water-based Development | Second Generation |

| BOYAN-ADC-90-Mk1 | Chemical Intensification Development | 90×90cm | Chemical Cleaning | First Generation |

Application area

PV Cell Screens

Ultra-Fine PCB

Glass Printing/Ceramic Electronics

Textile & Apparel

Silicone Label Printing

Webbing Screen Printing