K3 Screen printing squeegees, silk screen squeegees, PU squeegees

Screen printing squeegees which also called silk screen squeegees or PU squeegees are key materials for the screen printing process. Their main function is to transfer ink or coating layers onto the substrate via the screen mesh. Most screen printing squeegees are made of PU material. Depending on the characteristics of the substrate in screen printing, the precision requirements of the printed pattern, and the printing method, squeegees with different hardness levels and cross-sectional shapes can be selected.The hardness of a squeegee specifically refers to the hardness of its surface. It is usually expressed in Shore hardness, with available hardness grades of 55°, 60°, 65°, 70°, 75°, 80°and 85°, corresponding to three types: soft, general-performance, and high-wear-resistance. Common cross-sectional shapes include right angle, obtuse angle, and sharp angle.

As professional screen printing accessories, these squeegees are widely used in high-precision printing scenarios (e.g., garment printing, label printing, electronic printing). Choosing the right squeegee significantly improves printing quality and production efficiency.

Technical Specification

Screen printing squeegees press the printing material during the process, transferring the ink/coating from the screen mesh’s text/graphics area to the substrate.

Squeegee Selection

Straight-edge squeegee: A common shape with good conformability, capable of withstanding high pressure.

harp-edge squeegee: High flexibility and conformability, requiring less pressure—ideal for printing on uneven or irregularly shaped substrates.

Obtuse-angle squeegee: Combines straight and sharp-edge properties, reducing the risk of screen damage.

Technical Parameters

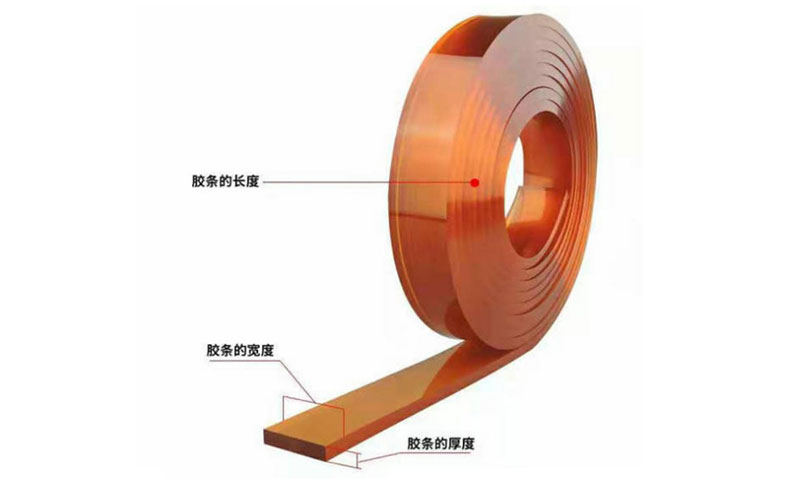

| Standard Length | 3660mm per roll |

| Hardness Range | Type A: 45°–65° (Soft squeegee, suitable for uneven surfaces) |

| Type B: 55°–80° (General-performance, suitable for various prints) | |

| Type C: 75°–95° (Wear/chemical resistant, suitable for fine pattern printing) | |

| Width | 5—200mm |

| Thickness | 1—20mm |